The Roman Maritime Concrete Study (ROMACONS):

Research at the Roman Harbour of Chersonisos in Crete, 2001 and 2007

Chris Brandon (Architect,

London), Robert L. Hohlfelder (University of Colorado), John Peter Oleson

(University of Victoria), and Charles Stern (University of Colorado)

Abstract

Vitruvius stated that it was

necessary to use pozzolana from the Naples region in Italy to make hydraulic

concrete that could set underwater. How extensive was the use of this

particular material? We know that pozzolana was shipped across the

Mediterranean from Italy to Israel for the construction of the major harbour of

Caesarea. But did the Romans also export it to minor cities such as Chersonisos

in Crete to build the concrete moles for its harbour? The Roman Maritime

Concrete Study (ROMACONS) was established to answer these questions and others

related to the use by the Romans of this extraordinary technology. This article

reports on field research in 2001 and 2007, along with follow-up analysis in a

laboratory.

Introduction:

The Roman harbour of Chersonisos in Crete and its Italian connection

Sometime between

30 and 20 BC Marcus Vitruvius Pollio wrote a treatise on architecture in which

he explains how harbours should be built at sites where there is no natural shelter

(De architectura

5.12.1-7). He described how to construct underwater concrete foundations and

structures that would form the artificial enclosing arms for harbours.

Pre-Roman solutions generally included rubble or ashlar block breakwaters and

moles. Although these methods continued to be used throughout the Roman era,

another technique was introduced that revolutionized the design of harbour and

other maritime structures – the use of hydraulic concrete. This material,

which could be cast and set underwater, began to be used in harbour structures

sometime in the second century BC (Gazda 2002; Oleson 1988; Oleson et al. 2004,

2006). Roman architects and engineers were free to create structures in the sea

or along shorelines that previously would have been difficult or impossible to

achieve. The active ingredient that reacted with the lime to form the hydraulic

variant was pozzolana, a volcanic ash from the Campi Flegrei at the north end

of the Bay of Naples, and made what we now call a pozzolanic concrete or

mortar. Probably by accident, Roman builders found that when volcanic ash sand

from quarries around the Bay of Pozzuoli was mixed with lime it made a stiff

mortar that could be laid and cured underwater. Contained within formwork and

laid in layers with large lumps of stone or tuff aggregate, it would set into a

solid mass that has proved to resist the ravages of the sea for over two

thousand years. Unlike lime mortars made with hydrated lime and inert siliceous

sands that react with carbon dioxide in the air to reform into “man-made”

limestone, pozzolanic mortars are made with a highly reactive aluminosilicate

component (pumice and volcanic ash) that when mixed with lime generates

reaction products that take the form of gels; rods; fibres and plates that give

strength and bind all the materials together (Lechtman and Hobbs 1987). Roman

builders usually made lime that was free of impurities, such as clay, and it

was consequently non-hydraulic.

Vitruvius

recommends that when building structures of concrete in the sea, the pozzolanic

material should ideally be taken from around the Bay of Pozzuoli. We now know

that the Romans were prepared to transport and ship this material for thousands

of kilometres in order to ensure that they could use this technology. In 1991,

chemical analysis carried out by Oleson and Branton on the pozzolana used in

the concrete at the late first century BC Roman harbour of Caesarea Palestinae

found that it had been shipped in bulk freighters 2000 km from the Bay of

Naples (Oleson and Branton 1992). The only known shipwreck that carried a

secondary cargo of pozzolana from the Naples area was the large Roman merchant

vessel that sank around 75-60 BC off the harbour of Madrague de Giens in the

South of France (personal communication, Patrice Pomey). How widespread was

this trade and the use of Vesuvian ash-based pozzolanic hydraulic concrete? To

answer this and other questions that relate to the nature of the concrete used

by the Romans in maritime structures, whether harbour moles, jetties, bridge

footings or fishponds, the authors established ROMACONS: The Roman Maritime

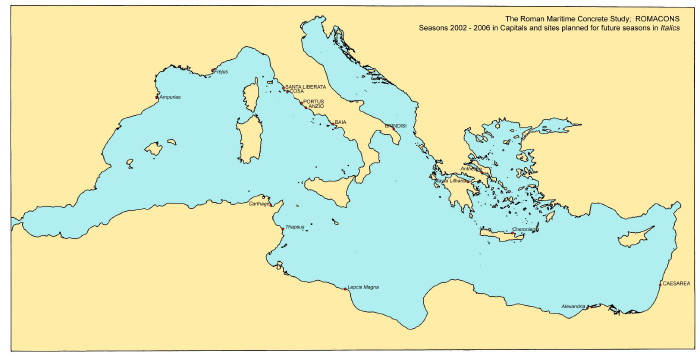

Concrete Project. Our database of known sites is extensive, spreading across

the whole Mediterranean, and ranges in date from the second century BC to the

Byzantine era. In addition to collecting small samples, between 2002 and 2008

we have collected 33 large cores (9 cm in diameter and up to 5.8 m long) from

32 sites in Italy, Israel, Egypt, and Greece, using a hydraulically driven

coring device with diamond bit (Hohlfelder 2008; Hohlfelder et. al. 2005;

Oleson et al. 2004, 2006). (Figure 1: map of sites cored).

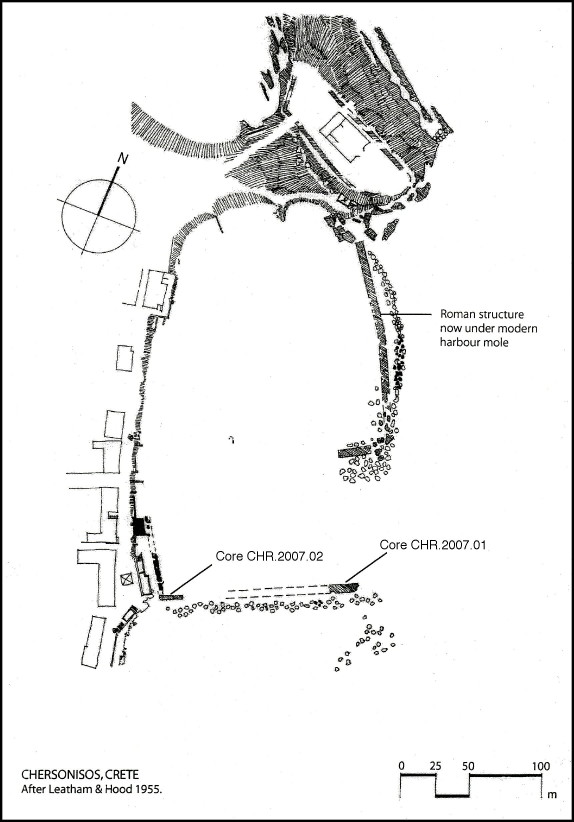

One of the first

harbours investigated was the Roman harbour at Chersonisos (Limin Khersonisou)

on the northern coast of Crete. This minor Roman harbour (270 x 150 m in size)

was founded on a small Hellenistic haven that was sited in the lee of a

headland called Kastri. The Roman improvements to the Hellenistic harbour

consisted of the addition of concrete moles to the rubble breakwaters to the

south and east, and concrete quays along the shore (Figure 2: plan of harbour,

after Leatham and Hood 1958-59).

We knew that the

Romans were prepared to ship vast quantities of pozzolana and tuff across the

Mediterranean from Italy to Caesarea in what is now Israel. But did they also

export it for use in the construction of smaller provincial harbours such as

Chersonisos? In 1955 and 1956 the ancient harbour of Chersonisos was surveyed

by John Leatham and Sinclair Hood (Leatham and Hood 1958-59). Since then, a new

harbour and the resort of Limin Khersonisou have developed and the majority of

the Roman moles are buried under the modern marina. However, the mole to the

south and the quay on the west are untouched and were the source of the samples

taken in October 2001 and September 2007.

The southern mole

is preserved for a length of 22.7 m in two parts and stands within 3.3 m of

water to just below sea level. Concrete quays extend along the shoreline on the

west of the harbour and remain in evidence for a length of 30 m and

approximately 2.6 m wide. The long “L” shaped eastern mole that now lies hidden

under the modern concrete breakwater was originally 150 m long with a 30 m long

return and between 5.2 to 5.3 m wide. Leatham and Hood described it as being

well preserved and faced with small squared blocks of stone that remained

in-situ at the level of the seabed. Along the inner surface of the mole were

recorded a series of vertical recesses set at 6.8 m centres alternately 1.0 m

and 1.5 m deep and between 0.6 to 0.8 m wide. These were initially thought to

have been either recesses that housed wooden steps or timber fenders. It is

more likely that these were the remains of the original formwork within which

the concrete was cast. Was this was an inundated structure where the mix of

lime, pozzolana and aggregate was placed underwater, or was it a double-walled

drained form that allowed an ordinary sand lime mortar and rubble fill to be

placed within a stone-faced mole all built in a dry environment? The presence

of pumice in a sand lime mortar does not necessarily mean that it was purposely

made to be hydraulic. In Crete there is significant contamination of the soils

from pumice and ash that originated at Santorini. If local sands were used in a

conventional air-cured mortar, it would also have pozzolanic properties that

would show up in analysis. The geological signature of any Santorini pumice or

volcanic ash, however, would be distinctly different from pozzolana from Naples

or elsewhere.

Leatham and Hood

mentioned that the original top surface of the moles remained in only a few

places and were almost flush with the current sea level. This change in

relative level to the sea, together with the presence of drowned fishpond on

the south eastern tip of the Kastri headland, indicates that the sea level has

risen approximately 1 m since the Roman era. The harbour is now fairly shallow,

with a maximum depth of 3m to a sandy bottom that has obviously silted up over

the course of time.

In October 2001 a

permit from the Ephorate of Underwater Antiquities and the Director of

Conservation allowed us to take five samples 3 cm in diameter and 10 cm in

length from the remains of the concrete moles. Chris Brandon carried out the

sampling on 14 October 2001. The British School at Athens supported the

application, and we are indebted to David Blackman, Director of the School at

the time, for his guidance and assistance. We also thank Katerina Delaporta and

Elpida Hadjidaki of the Ephorate of Underwater Antiquities without whose help

we could not have carried out the work. Due to the limited time available and

the restriction on the sample size, it was decided to collect them with steel

tubes driven into the concrete matrix or mortar using a 2-kg lump hammer. Five

30-cm long hardened stainless steel coring tubes with an external diameter of

3.2 cm were individually driven into the moles at selected sites. The samples

of mortar within the tubes were retained for later removal on shore and sent

for analysis at the University of Colorado. The mortar samples were

analysed by Charles Stern of the Department of Geological Sciences, University

of Colorado, Boulder. The ratio of mortar to aggregate was much lower than at

the other sites that had been studied. Preliminary measurements indicate the

intervals among the large aggregate at Chersonisos average approximately 4 cm,

whereas at Nero’s harbour of Antium (Anzio) it is 7.9 cm, at the Claudian

harbour of Portus 11.9 cm, and at the Trajanic harbour of Portus 4.7 cm. This

meant it was difficult to find locations on the surface of the marine encrusted

remains where there was a sufficient quantity of mortar that could be sampled

with the hammer driven corer. In the end only fragmentary samples were

collected, confirming the inadequacy of this method of surface collecting

concrete samples.

Microscopic

examination and petrographic analyses of two thin sections cut from the light

grey white mortar from a sample taken from the western end of the southern mole

(CHR.2001.02), showed that 50 percent of the sample consisted of a fine grained

matrix of mortar. The mortar contained aggregate clasts of the following

materials:

Grey

and yellow pumice fragments ranging between 1 and 10 mm in diameter for 30% of

the volume of the sample. Pumice consisted of clear and colourless to pale

brown glass and contained crystals of feldspars, biotite, and green

clinopyroxene, and vesicles that vary between rounded to highly elongated

Grey,

red and black volcanic rock and individual crystal fragments ranging between 1

and 4 mm in diameter for 10 % of the volume of the sample. Rock fragments

include both light coloured felsic and red and black mafic igneous rocks.

Crystal fragments include quartz, plagioclase, biotite and green clinopyroxene,

all also found as crystals in either pumice and rock fragments.

White

calcite and lime fragments ranging between 1 and 10 mm in diameter for 10 % of

the volume of the sample.

The other samples

of mortar had a similar composition, and it was established that it was

representative of all the concrete used at Chersonisos.

A pumice separate

was extracted by hand from the consolidated sample CHR.2001.02 and analysed for

chemical composition. It appears that the pumice ash contained within the

mortar has much in common with volcanic material from Italy, for example a very

high K2O content (>6 wt %) and total alkali element concentration (Na2O +

K2O > 10 wt %) for a rock with an intermediate silica concentration (SiO2 =

60 wt %). This pumice did not derive from the island of Santorini to the north,

which typically would have lower K2O (<3 wt %) and total alkali

concentration (<8 wt %) even for pumice with very high silica concentration

(SiO2>70 wt %). Although it may possibly have come from the island of Kos or

even Southwest Turkey, where highly alkaline volcanic rocks also occur, it more

probably was sourced from Italy.

The restrictions

imposed on surface collected samples severely limited the range of analysis

that could be carried out. It was also apparent that Roman concrete was not

homogeneous and surface samples were unlikely to be truly representative of the

whole.

In

September 2007 a larger team including C. Brandon, J. P. Oleson, and D.

Klapecki returned to Chersonisos. With the kind assistance of Mr. Tolis

Vougioukas, we arranged for the rental of a small boat and boat tender to carry

our coring equipment (Figure 3, boat with equipment).

With

the diligent assistance of the Director of the 23rd Ephorate of

Prehistoric and Classical Antiquities in Heraklion Ms. Maria Bredaki, we

arranged for Ms. Eirini Karousou to observe our field work on 11 and 12

September. The weather and sea conditions were excellent, and two cores were

recovered from the Roman period breakwater in the harbour basin (Figure 1, plan

of harbour). After removal of the cores, the coring holes were filled with

local sand to within 10 cm of the surface of each block. The remainder of each

hole was then filled with a mortar composed of the same materials as the

ancient block: lime and pozzolana. (Figure 4: Boat and coring equipment at CHR.2007.01)

Preliminary

Description of the 2007 Cores:

CHR.2007.01.

Location:

pila in water, second from the end of the mole on the east side of harbour,

central northern portion. UTM 353943 E 3909741 N.

Water

depth: 0.70 m.

Depth

of core hole: 1.90 m; the base of the wall was not reached

Size of

recovered core: 1.2 m, all fragmentary; no section longer than 0.12 m.

Comments:

The mortar was very crumbly, so only small portions survived the coring

process. The poor cohesion between the mortar and the aggregate allowed much of

the core to grind itself away. The longest intact mortar section was 0.10 m

long. The mortar seems very open and degraded. Possibly it was low in lime,

either because of a poor mix, or from loss through chemical action or erosion.

The mortar and aggregate both appear to be poorly sorted and poorly mixed,

including fairly large chunks of tuff (up to D 0.028 m), large voids where a

crumbly black mineral has fallen out (D 0.016 m, 0.014 m), and aggregations of

lime nodules (D 0.002-0.004 m).

CHR.2007.02

Location:

quay wall near south shore of harbour, exposed above waterline. UTM 353835 E

3909705 N.

Depth

of core hole: 1.52 m; the base of the wall was reached.

Size of

recovered core: 1.49 m, in several sections; the longest section is 0.20 m.

There was a small amount of grinding between 2 sections. (Figure 5:

CHR.2007.02)

Comments:

The mortar seems very porous and granular, perhaps poor in lime. The lime

nodules range in size from 0.004-0.025m, although mostly smaller. In addition

to possibly being short of lime, it is probable that this mortar was not

compacted; it simply looks very loose. There are small pieces of tuff, ranging

from 0.005-0.035 m, predominantly in the middle of this range. The kurkar aggregate is very

irregular in size and shape, and irregular in distribution, from D 0.05 to D

>0.18 m. It constitutes approximately 40% of the core.

The cores are at

present awaiting chemical and structural analysis at the Italcementi laboratory

in Bergamo.

Bibliography

Gazda E. K., 2002,

“Cosa’s Contribution to the Study of Roman Hydraulic Concrete: An

Historiographic Commentary,” in N. W. Goldman, ed., New Light from Ancient

Cosa, Classical Mediterranean Studies In Honor of Cleo Rickman Fitch, New York, pp. 147-77.

Hohlfelder, R. L.,

2008, “The Roman Maritime Concrete Study: A Brief Summary of Fieldwork from

2002-2005,” in R. L. Hohlfelder, ed., The Maritime World of Ancient Rome, Ann Arbor, pp. 297-304.

Hohlfelder, R. L.,

Brandon, C., and Oleson, J. P., 2007, Constructing the Harbour of Caesarea

Palaestina, Israel: New Evidence From the ROMACONS Field Campaign of October

2005, The International Journal of Nautical Archaeology 36: 409-15.

Leatham J., and S.

Hood, 1958/59, “Sub-Marine Exploration in Crete, 1955,” The Annual of the

British School at Athens, 53-54:

263-73.

Lechtman H. N., and

Hobbs L. W., 1987, “Roman Concrete and the Roman Architectural Revolution,” Ceramics

and Civilization,

vol. 3, Columbus OH, pp. 81-128.

Oleson J.P., 1985,

“Herod and Vitruvius: Preliminary Thoughts on Harbour Engineering at Sebastos,

the Harbour of Caesarea Maritima,” Harbour Archaeology. Proceedings of the

First International Workshop on Ancient Mediterranean Harbours, Caesarea

Maritima,

British Archaeological Reports, Intl Series, 257, Oxford, p. 165-172.

Oleson J.P., 1988,

“The Technology of Roman Harbours,” International Journal of Nautical

Archaeology 17:

117-29.

Oleson J. P., and

Branton G., 1992, “The technology of King Herod’s harbour,” Caesarea Papers,

Straton’s Tower, Herod’s Harbour, and Roman and Byzantine Caesarea, Journal of Roman Archaeology

Supp. 5, Ann Arbor, p. 49-67.

Oleson, J. P.,

Brandon, C., Cramer, S. M., Cucitore, R., Gotti, E., and R. L. Hohlfelder,

2004, “The ROMACONS Project: A Contribution to the Historical and Engineering

Analysis of the Hydraulic Concrete in Roman Maritime Structures, International

Journal of Nautical Archaeology 33.2:

199-229.

Oleson, J. P.,

Bottalico, L., Brandon, C., Cucitore, R., Gotti, E., and R. L. Hohlfelder,

2006, “Reproducing a Roman Maritime Structure with Vitruvian pozzolanic

concrete,” Journal of Roman Archaeology 19: 31-52.